Introduction

This page documents ongoing attempts to produce a rich, variegated green glaze using an iron/phosphorus mechanism in cone 6 borosilicate glaze.

Some key takeaways so far:

- A lithium-rich base produces a better green than a soda or potash base

- A small addition of lanthanum oxide appears to brighten the effect without changing the color

Iron/Phosphorus Glaze

Blue Hare, Hare’s Fur, or Floating Blue is a widely used effect in pottery studio glazes and commercial glazes.

The effect is observed in saturated iron-rich glazes with the addition of a titanium or phosphorus source. The range of expressed colors varies depending on the base composition of the glaze - usually a greenish-blue but it can tend either way.

I opted to pursue the iron/phosphorus approach, both to build upon existing work and for personal preference. An iron/titanium basis might serve just as well.

Inspiration

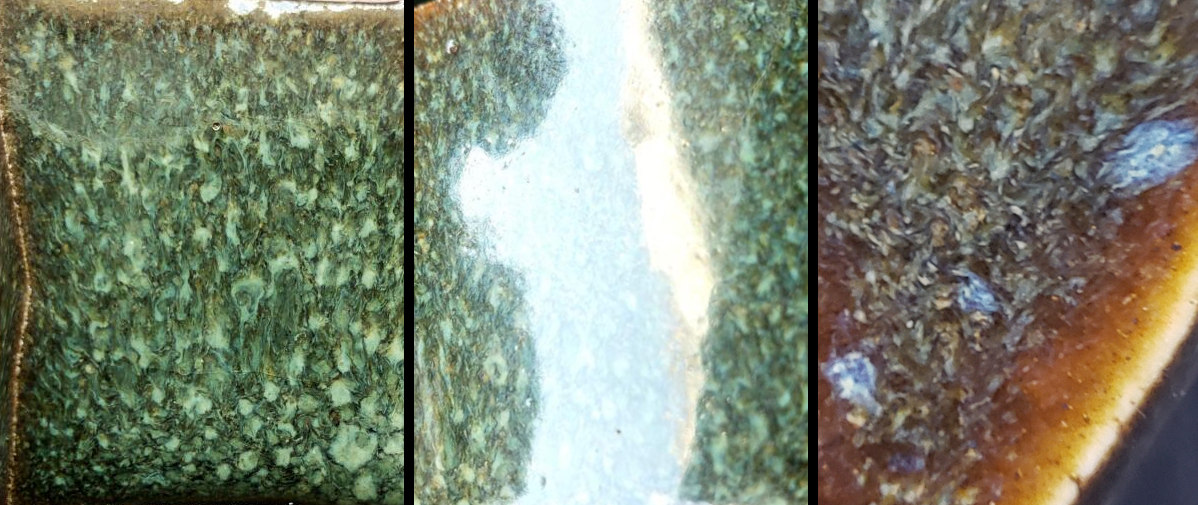

In 2023, Clara Giorello published the recipe for a glaze experiment called Selva / Jungle, which aimed to produce the Blue Hare effect. The result was unexpectedly green, much greener than any reactive iron/phosphorus glaze I’ve seen. On certain test samples, strange isolated blue spots are observed, which implies two different reactions might be occurring.

Early Attempts

I began my first attempts to replicate Selva / Jungle without much success - the test tile was amber with only slight signs of blue nucleation points.

I managed to get some colored streaks by adding rutile (titanium). This new base recipe led to some promising tangents, but nothing was close to the intended effect.

The next attempts involved matching Clara’s instructions as closely as possible:

- Located feldspar and kaolin whose analyses more closely matched ingredients from Argentina

- Used an identical cone 7 kiln firing schedule

- Tried homemade bone ash as my phosphorus source

None of these modifications seemed to offer any improvement, and every test looked more or less like the brown tile pictured above.

Breakthrough #1 - Saturation

The first significant progress toward green coloration involved removing some kaolin from the recipe to better saturate the glass. This almost immediately produced a toothpaste-green when fired at cone 7.

Around this point I gave up trying to crack the original recipe, thinking there must be some unknown material factor that I’d never be able to replicate. Instead it would be more interesting and productive to focus development on new ideas. Furthermore, while firing hotter seemed to tip the color in the right direction, I preferred to achieve the effect without requiring a particular kiln schedule.

Breakthrough #2 - Lithium

Next, I focused on varying primary and secondary fluxes. Early on I established that even small additions of magnesium would turn everything brown. The glaze already contained calcium, sodium, and small amounts of potassium, so the first test involved shuffling oxides to modify their percentages.

My initial hypothesis was that replacing sodium with potassium would help shift the color towards green. I decided to experiment with lithium as well, since it would help reduce crazing caused by the low kaolin content.

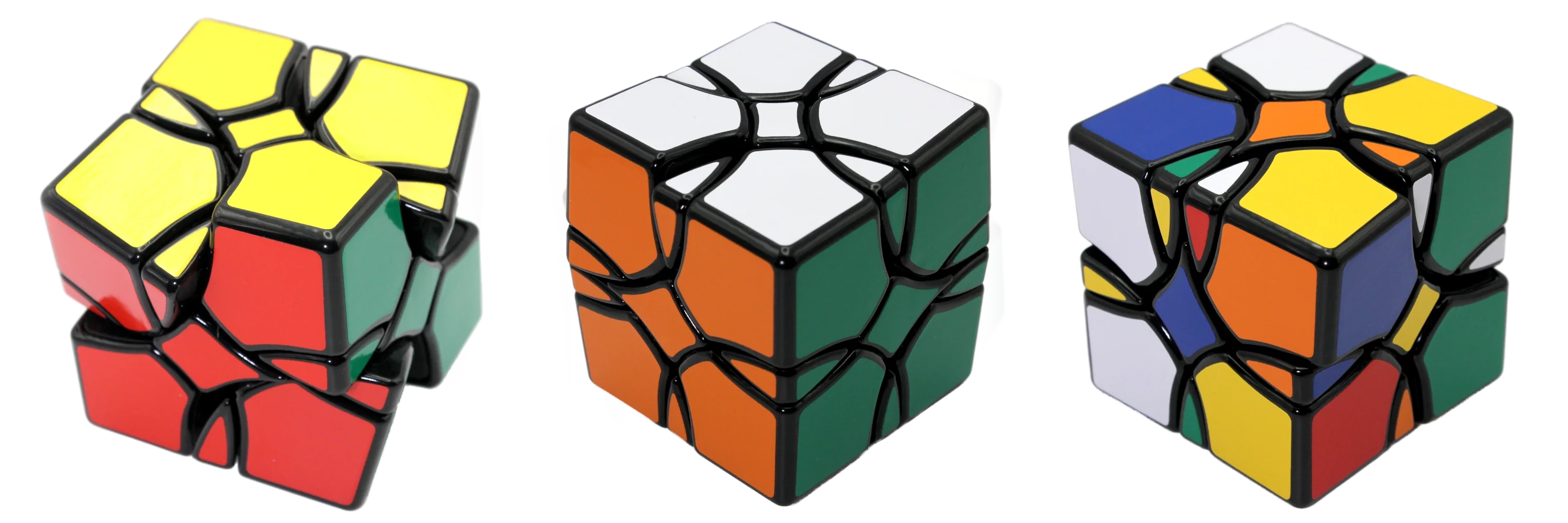

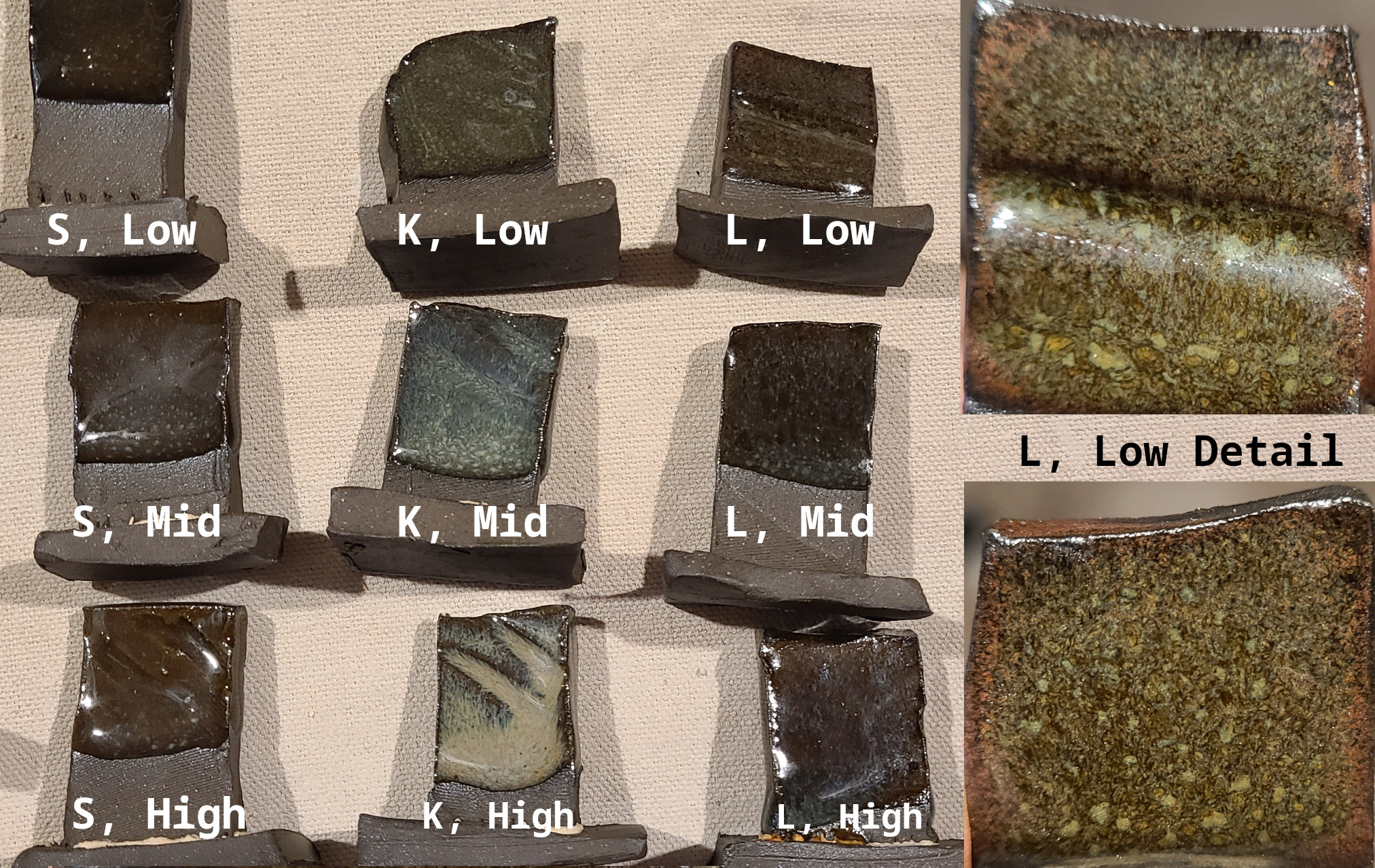

In the test above, the left column is a high-sodium base (Minspar), the middle a high-potassium base (Mahavir feldspar), and the right a potash + spodumene base that replaced much of the sodium with lithium. From top to bottom the calcium was varied.

This test was perhaps too coarse to draw any hard conclusions, but I was very excited about the low calcium, lithium base (top right) tile. It was faint, but close inspection under light revealed predominantly green and yellow streaks, with a complete absence of blue.

Oddly, this tile also precipitated iron on the edges - the only time I’ve observed this in any test.

Breakthrough #3 - Lanthanum

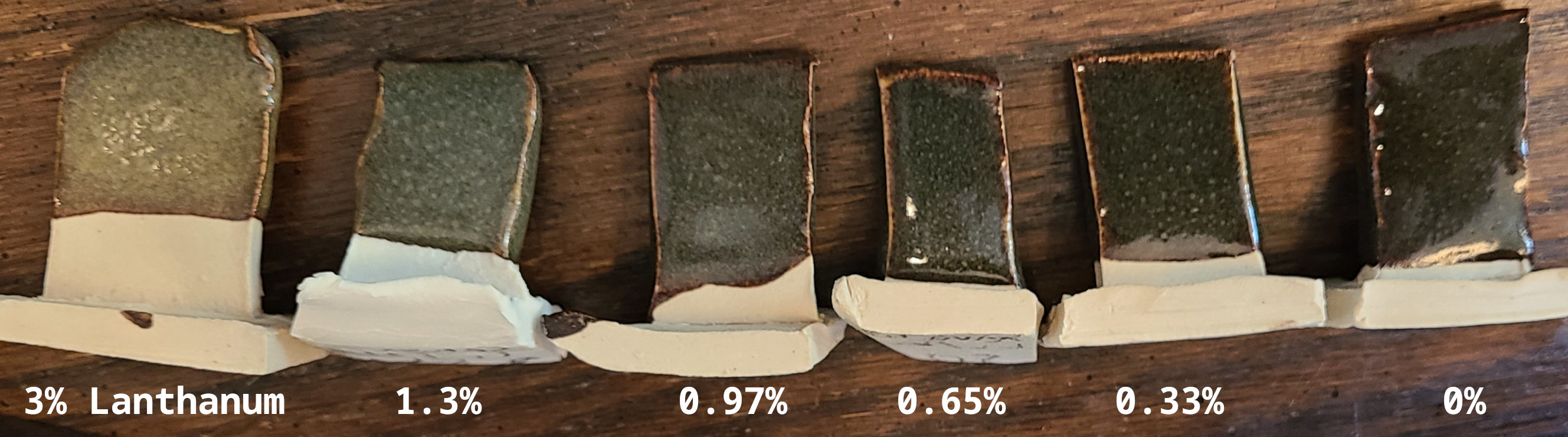

Some failures later, I hail-mary’d 3% lanthanum oxide into the best lithium-based formula. Very surprisingly, it brightened the initial dark green color to a light army green, without introducing any blue.

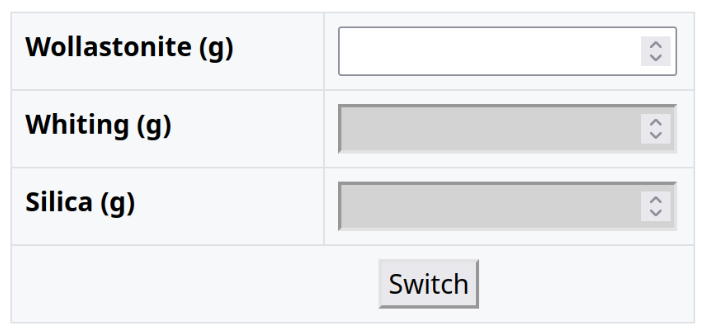

To explore this more I tested a line blend, starting from the lithium base (right), and gradually adding lanthanum oxide while removing an equivalent amount of whiting.

The 0.65% - 1.3% lanthanum oxide range produced by far the best greens yet.

Checkpoint - v1.7

I was happy enough with the results at this point to start glazing some pieces. This version is published on Glazy.org as ‘Selva / Jungle (USA)’ v1.7.

Pros:

- Decent thermal expansion, fits my porcelain and stoneware without crazing

- Designed for cone 6, slow cool

Cons:

- Variegation / phase separation is not as pronounced as I’d like

- There’s very little clay in the recipe, so mixing a bucket of it is maybe not a good idea. Future revisions will incorporate more clay and less feldspar

Further experimentation to-do (06/29/2025)

- Confirm theory that lanthanum oxide specifically is brightening the color - substitute other oxides and compare

- Biaxial blend of iron and phosphorus to try increasing translucency, contrast, and phase separation

- Fine-tune the primary fluxes (lithium, potassium, and sodium) for the best green

Lanthanide Experiment (December 2025)

I tried replacing lanthanum oxide with other lanthanide oxides to see if they performed similarly. In general, the test was a failure; due to changes in my mixing procedure, the glazes were too watery. The test tiles (not pictured) tentatively confirmed that equal amounts of samarium and yttrium oxides by weight have a similar brightening effect as lanthanum oxide. I also tried tin oxide as a control, which just opacified the glaze and turned it brown.

Two possible hypotheses:

- The lanthanides are helping to saturate the glass, making smaller amounts of iron more effective

- The lanthanides are acting similarly to a strong alkaline earth flux and could be subbed with a cheaper alternative

La / Iron Triaxial Experiment (January 2026)

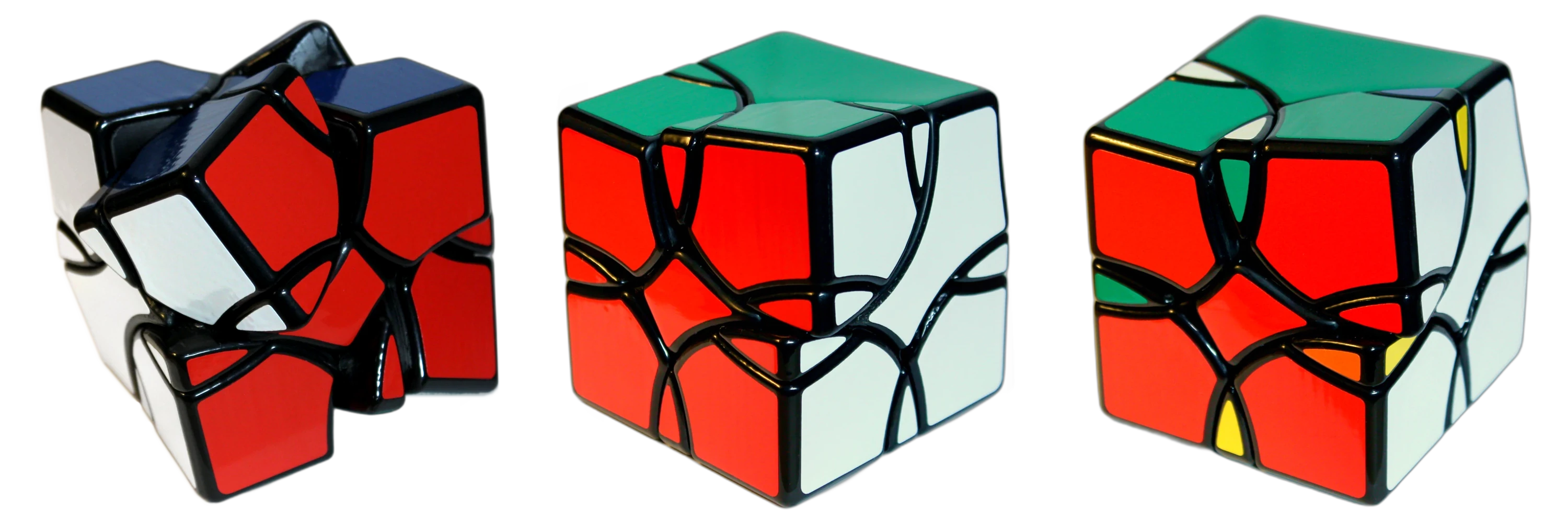

To test hypothesis 1, I constructed a triaxial experiment that replaced iron with lanthanum in various quantities.

The single best result from this test was tile 3, which had a 0.4% increase in lanthanum and a 1.3% reduction in iron. It’s once again difficult to draw any hard conclusions from this test, but I’m leaning toward hypothesis 2 being more accurate. At some point in the future I will try to eliminate the lanthanum oxide from the glaze, but for now I’ll keep it at a 0.6% fixed percentage for consistency.

The next test will be an iron/phosphorous biaxial grid in attempt to find a good balance between color and opacity.